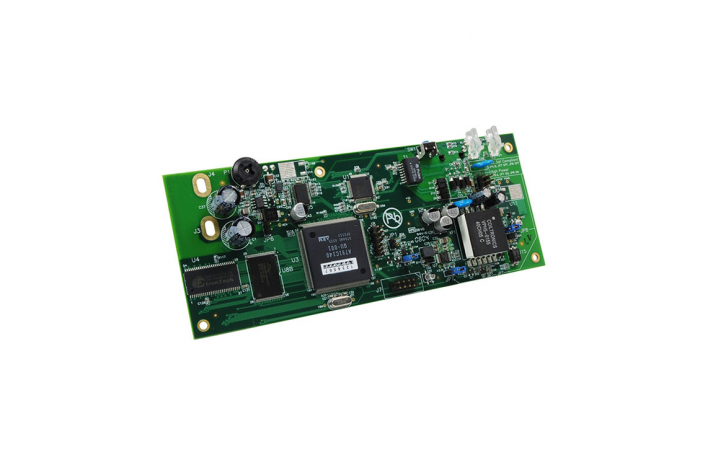

PCBA Manufacturing

PCB Assembly PCBA

Discover the Best PCBA Solutions

With over 6 SMT production lines and mounting capabilities of 7,600,000 pcs/day, DMAX provide industry-leading PCBA manufacturing services tailored to your needs. Our advanced technology includes DIP Wave Soldering, N2 Reflow for soldering quality enhancement, and comprehensive prototype and small-quantity support. Fully compliant with RoHS, REACH, and ISO standards, our PCBA assembly processes meet the highest global requirements. Whether you need prototype PCBA or economic order quantities starting at 500 pcs, we deliver reliable, scalable, and high-precision solutions for all your electronic assembly needs.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.jpg)

.png)

.jpg)

.jpg)

Q: Do You have a price list?

A: DMAX are an OEM manufacturer specializing in PCBA services.

We produce products based on the customer's designs and instructions.

Since our PCBA manufacturing processes are highly customized, we do not have a fixed price list.

Please contact us directly to discuss your PCBA assembly requirements.

Q: What's Your MOQ for PCB and PCBA?

A: DMAX have no MOQ (Minimum Order Quantity) for both PCB and PCBA assembly.

We offer prototype and mass production services.

For cost optimization, we provide Economical Order Quantity (EOQ), starting at 500 pcs.

Please send us your inquiry for detailed PCBA solutions.

Q: Can You do turnkey services? Can You procure all parts in the BOM for us?

A: Yes, we offer PCBA turnkey solutions, including BOM procurement.

However, the service depends on order quantity:

- For Mass Production (MP): We can process BOM procurement.

- For prototypes and pilot runs: We recommend the customer supply components for PCBA prototyping.

Contact us for further details about our PCBA turnkey services.

Q: What's your lead time (L/T) for PCBAs?

A: The typical lead time for PCBA manufacturing is 2 weeks.

For additional processes such as post-test and box build, lead time may extend to 3 weeks.

Precise instructions, SOPs, and fine test fixtures can expedite the PCBA lead time.

Q: What's your lead time (L/Y) for bare PCBs?

A:

- PCB Lead Time is within 2 weeks for quantities below 1,000 pcs.

- PCB Lead Time is 3 weeks for quantities above 1,000 pcs.

For more details about PCBA and PCB production, please contact us.

.jpg)